OUR COMPREHENSIVE RESOURCES ENCOMPASS PRODUCT CATALOGS, TECHNICAL SPECIFICATIONS, AND EXPERT SUPPORT, EMPOWERING CUSTOMERS WITH THE KNOWLEDGE AND TOOLS NECESSARY FOR INFORMED DECISION-MAKING.

At Electri-Cord (ECM), we prioritize providing comprehensive resources to our valued customers. We understand that informed decision-making and access to relevant information are crucial for successful collaborations. That is why we offer a wide range of resources to support our customers throughout their journey with us.

Our website features product catalogs, technical specifications, and datasheets that provide detailed information about our offerings. Additionally, we have a knowledgeable customer support team ready to assist with any inquiries or concerns. Whether it’s guidance on product selection, customization options, or troubleshooting, we are dedicated to ensuring our customers have the resources they need to make informed choices and achieve optimal outcomes.

- Ordering Instructions

For your convenience, request a quote with our Online Product Specification Order Form, also available for download/print in PDF format. Our dedicated sales team is available to help you through the order or inquiry process – so contact us with your questions about product or process. To ensure the most accurate quote possible, please provide as much of the following information when placing an order or making an inquiry:

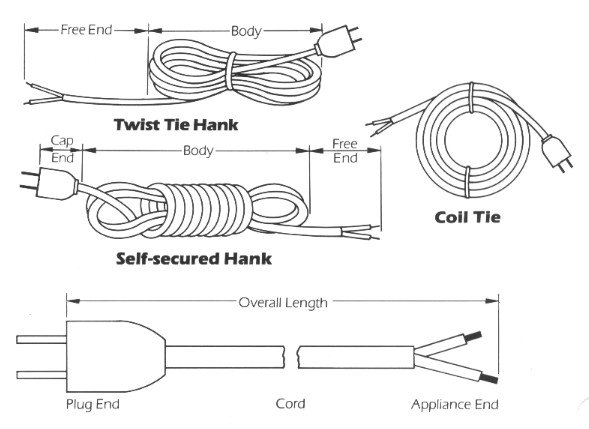

Overall length from the face of the plug to end of the longest conductor

- AWG size & number of conductors

- Color & UL type designation

- Plug type

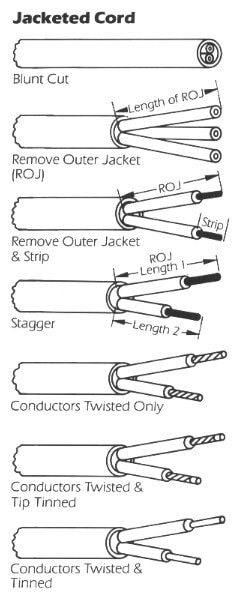

- Appliance end finish: – Molded connector (specify by category number) – Power supply cords (describe end processing from Standard Factory Tolerance chart below)

- Strain Relief: – Specify by category number – Indicate location as center-line to end of longest conductor

- Put-up: – Hanked-self-secured (specify body and free-end lengths) – Unhanked-tied in bundles.

- Coiled – (specify critical diameter and free-end lengths) – Required approvals (UL and/or CSA)

Overall length up to 10 ft Plus or Minus 1 in. over 10 ft Plus 2 in. Minus 1 in. Split or Jacket Removal Plus or Minus 1/4 in. Strip Plus or Minus 1/16 in. Location of Molded Strain Relief Plus 1/4 in. Minus 1/8 in. Stagger Plus or Minus 1/8 in. Hank Cap End Plus or Minus 1 in. Body Plus or Minus 1 in. Free End Plus or Minus 2 in. - Glossary

Metric to Standard Standard to Metric

25.4 mm per inch

305 mm per foot

.305 M per foot

1.61 KM per mileStandard to Metric

.03937 inches per mm

39.37 inches per meter

3.28 feet per meter

.622 miles per KMGlossary of Wire Type Terminology

Flat Wire: SPT: Stranded, Parallel, Thermoplastic

This is always followed by a -1, -2 or -3, signifying insulation thickness for different applications.

HPN: Heater, Parallel, Neoprene

Required for heater-type application, such as irons, toasters, etc.

NOTE: Electri-Cord can run some 20 AWG, but mostly we run 18, 16 and 14 AWG, 2 or 3 conductors.

P = Parallel Wire (Flat).

Jacketed Wire:S = Stranded (or Service Wire)

J = Junior Service (300 Volt). If no “J” is in the wire type, then it is a hard service (600 Volt).

T = Thermoplastic. If no “T” is in the wire type, then it has a rubber jacket.

O = Oil-Resistant Compound

W = Weather-Resistant Compound

V = Vacuum (as in vacuum cleaner). This is a small O.D. jacketed wire, very flexible and initially used for vacuum cleaners but now used on many different types of products. Available only in 18 AWG.Examples:

SV = Stranded Vacuum Rubber Jacketed (NO “T”)

SJT = Stranded Junior Thermoplastic

SJTOW = Stranded Junior Thermoplastic, Oil and Weather resistant for UL and CSA.Miscellaneous requirements:

S.P. = Surface Printed

N.M. = Non-Migratory compound to prevent the wire color from bleeding under unusual circumstances.

VW-1 = Vertical Flame test (formerly FR-1)

IEC, ICC = International Color Code on the inner conductors (Blue, Brown, Green w/Yellow Stripe)

N.A. = North American Color Code on the inner conductors (Black, White, Green)

41/34 = Stranding specification format (41 strands of 34 AWG wire for each inner conductor)

T.C. = Tinned Copper inner conductors|

RIBBED = Outer jacket is striated with ribs

R/S or W/S = Red or White Stripe for visual polarity inspection on Flat wireTemperature Ratings:

60°C = Standard rating (except HPN =90°C)

105°C = Electri-Cord’s alternate rating

(we normally don’t stock 75°, 90°C)Inner Conductor Colors

Function North American (NA) International (ICC) Hot Black Brown Neutral White Blue Earth (Ground) Green Green w/Yellow Stripe Metric Conversion Chart:

In. Dec. mm In. Dec. mm In. Dec. mm 1/32 .031 .793 11/32 .343 8.731 11/16 .687 17.462 1/16 .062 1.587 3/8 .375 9.525 23/32 .718 18.256 3/32 .093 2.381 13/32 .406 10.318 3/4 .750 19.050 1/8 .125 3.175 7/16 .437 11.112 25/32 .781 19.843 5/32 .156 3.968 15/32 .468 11.906 13/16 .812 20.637 3/16 .187 4.762 1/2 .500 12.700 27/32 .843 21.431 7/32 .218 5.556 17/32 .531 13.493 7/8 .875 22.225 1/4 .250 6.350 9/16 .562 14.287 29/32 .906 23.018 9/32 .281 7.143 19/32 .593 15.081 15/16 .937 23.812 5/16 .312 7.937 5/8 .625 15.875 31/32 .968 24.606 21/32 .656 16.668 1 1.000 25.400 - Cordset Cross-Reference

Belden Trade # Electri-Cord Ref. # Belden Trade # Electri-Cord Ref. # Belden Trade # Electri-Cord Ref. # 17009 ECM-009 17506 ECM-506 17607 ECM-607 17106 ECM-106 17507 ECM-507 17612 ECM-612 17109 ECM-109 17508 ECM-508 17613 ECM-613 17205 ECM-205 17509 ECM-509 17618 ECM-618 17236 ECM-236 17512 ECM-512 17619 ECM-619 17237 ECM-237 17513 ECM-513 17624 ECM-624 17238 ECM-238 17514 ECM-514 17629 ECM-629 17239 ECM-239 17516 ECM-516 17635 ECM-635 17250 ECM-250 17517 ECM-517 17636 ECM-636 17251 ECM-251 17518 ECM-518 17637 ECM-637 17254 ECM-254 17519 ECM-519 17740 ECM-740 17255 ECM-255 17520 ECM-520 17741 ECM-741 17276 ECM-276 17521 ECM-521 17742 ECM-742 17280 ECM-280 17523 ECM-523 17743 ECM-743 17405 ECM-405 17524 ECM-524 17745 ECM-745 17406 ECM-406 17525 ECM-525 17746 ECM-746 17407 ECM-407 17534 ECM-534 17747 ECM-747 17408 ECM-408 17535 ECM-535 17749 ECM-749 17409 ECM-409 17536 ECM-536 17750 ECM-750 17412 ECM-412 17537 ECM-537 17751 ECM-751 17419 ECM-419 17538 ECM-538 17752 ECM-752 17422 ECM-422 17539 ECM-539 17753 ECM-753 17425 ECM-425 17566 ECM-566 17757 ECM-757 17500 ECM-500 17567 ECM-567 17902 ECM-902 17501 ECM-501 17568 ECM-568 17903 ECM-903 17502 ECM-502 17569 ECM-569 17904 ECM-904 17503 ECM-503 17600 ECM-600 17905 ECM-905 17504 ECM-504 175601 ECM-601 17906 ECM-906 17505 ECM-505 17606 ECM-606 17952 ECM-952 We are able to cross-reference several of our other competitor’s part numbers as well. If the only description you have is someone else’s part number, the Electri-Cord problem solvers will be able to quote you immediately with our best price and delivery.

- Wire Size Specifications

Wire Type Dimensions Stranding Ampacity Weight Lbs./1,000 Ft. 20/2 POXT .096 x .185 26/34 3 18 18/2 SPT-1 .105 x .203 41/34 10 20 18/2 SPT-2 .140 x .262 41/34 10 29 16/2 SPT-2 .155 x .285 65/34 13 37 18/2 HPN .144 x .286 41/34 10 30 16/2 HPN .155 x .305 65/34 15 38 18/3 SPT-1 .110 x .303 41/34 10 31 18/3 SPT-2 .140 x .335 41/34 10 37 18/3 SPT-3 .170 x .380 41/34 10 48 16/3 SPT-2 .155 x .380 65/34 13 49 16/3 SPT-3 .185 x .435 65/34 13 62 14/3 SPT-3 .235 x .500 41/30 15 97 18/3 HPN .136 x .335 41/34 10 42 16/3 HPN .150 x .365 65/34 15 55 18/2 SVT .240 41/34 10 34 18/2 SVT .230 65/36 10 34 18/3 SVT .255 41/34 10 42 18/3 SVT .245 65/36 10 42 18/3 SVTO .260 41/34 10 42 18/2 SJT .298 16/30 10 44 16/2 SJT .330 26/30 13 57 18/3 SJT .320 16/30 10 59 16/3 SJT .345 26/30 13 72 14/3 SJT .375 41/30 15 94 12/3 SJT .445 65/30 20 136 18/3 SV .255 41/34 10 33 18/3 SJ .320 16/30 10 60 16/3 SJ .345 26/30 13 74 14/3 SJ .375 41/30 15 97 12/3 SJ .449 65/30 20 140 18/3 SJO .320 16/30 10 60 16/3 SJO .345 26/30 13 74 14/3 SJO .375 41/30 15 87 18/3 SO .382 16/30 10 92 16/3 SO .400 26/30 13 112 14/3 SO .549 41/30 15 192 Optional Stranding 18 AWG 16/30, 41/34, 65/36 16 AWG 26/30, 65/34 14 AWG 41/30 12 AWG 65/30 Note: Above dimensions are nominal and are within UL and CSA tolerances. If wire size or O.D. is critical to your application, please contact us for special arrangements.

- International Standardized Connectors

NEED TO CREATE TABLE BASED ON EXISTING INFORMATION

- International Connectors

NEED TO CREATE TABLE BASED ON EXISTING INFORMATION