Capabilities

With over 75 years in business, ECM has developed unique capabilities and supply chains to help benefit your business. Our list of capabilities extends far beyond the standard issue, we excel in contract manufacturing, custom wire solutions, global supply chain connections, product development, kitting and assembly, molding & overmolding, and quality control. Scroll down to view our full capabilities.

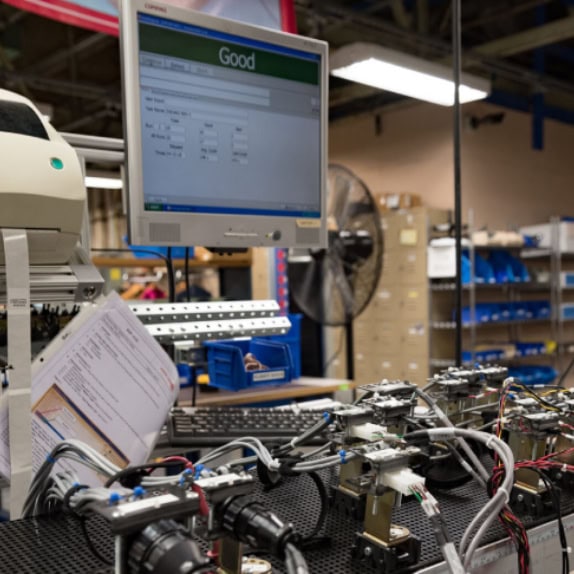

Contract Manufacturing

Delivering Manufacturing and Distribution Solutions to Thrive in the Global Market

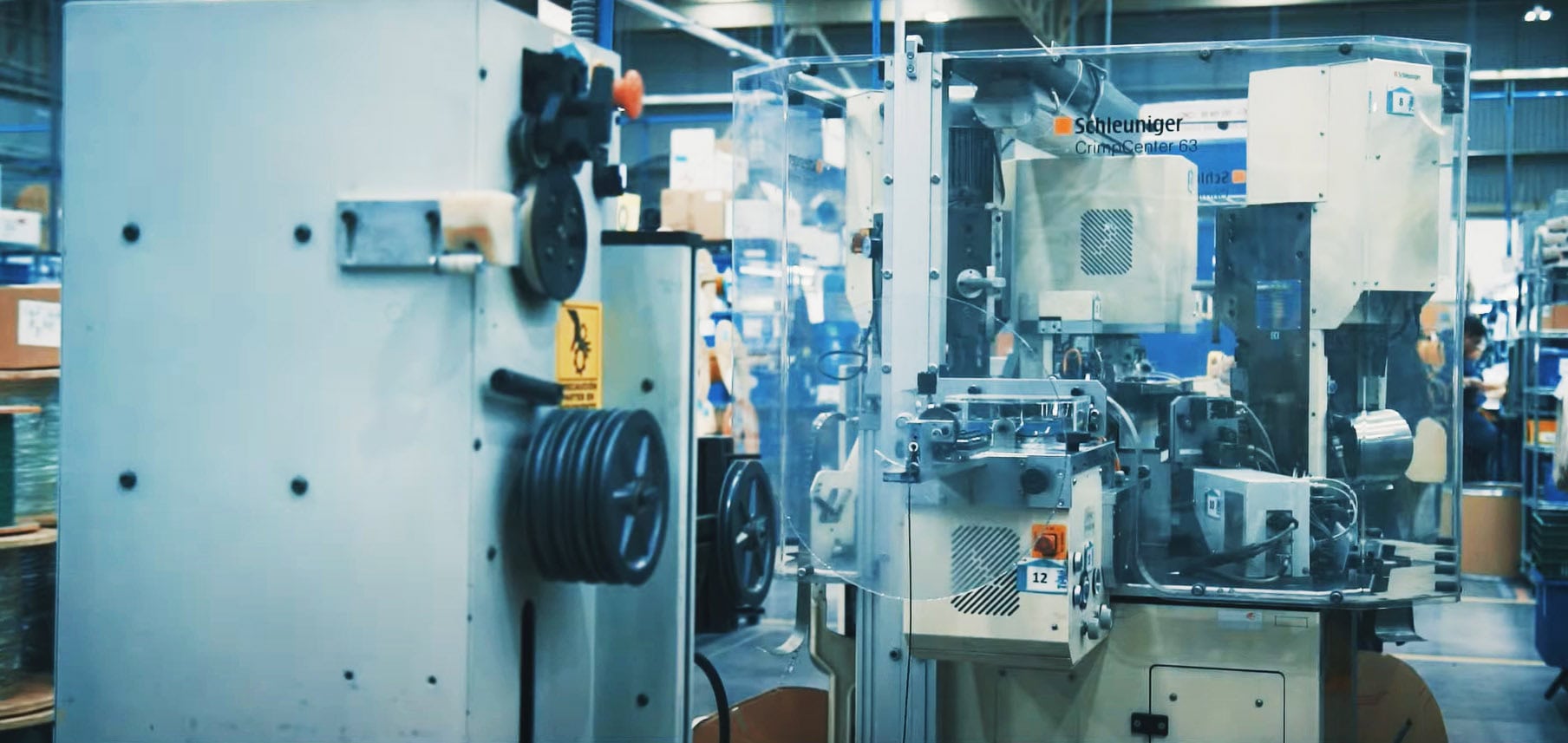

ECM offers turnkey solutions to produce products manufactured to your time, cost, and volume specifications. Combined with our Globally Local© approach to manufacturing, this is what makes us your trusted source for a variety of custom wiring solutions.

We offer custom wiring harnesses, cable assemblies, and other electronic services for your unique application. Custom electronic manufacturing ensures that your power cords, box builds, and other products are manufactured according to your exact specifications and required approvals, leading to more cost-effective and efficient processes.

For more than 75 years, ECM’s experienced team of engineers has developed high quality electronic solutions to serve our customers in a wide range of industries.

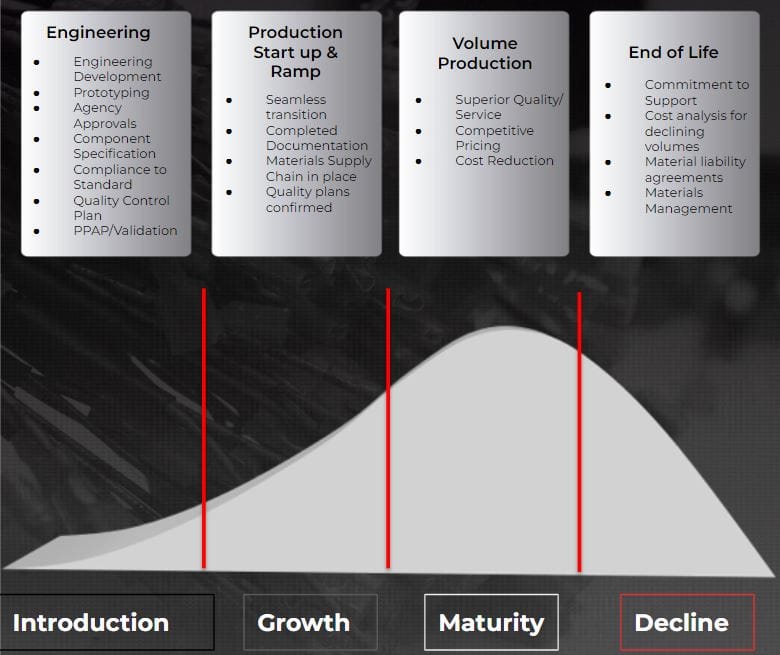

From initial concept and design all the way through production and end-of-life, we will work with you every step of the way to ensure your unique needs are met. Contact us to begin discussing your project requirements.

Custom Wiring Solutions

At ECM, we provide comprehensive solutions for manufacturing products that meet your specific requirements for timing, cost, and volume.

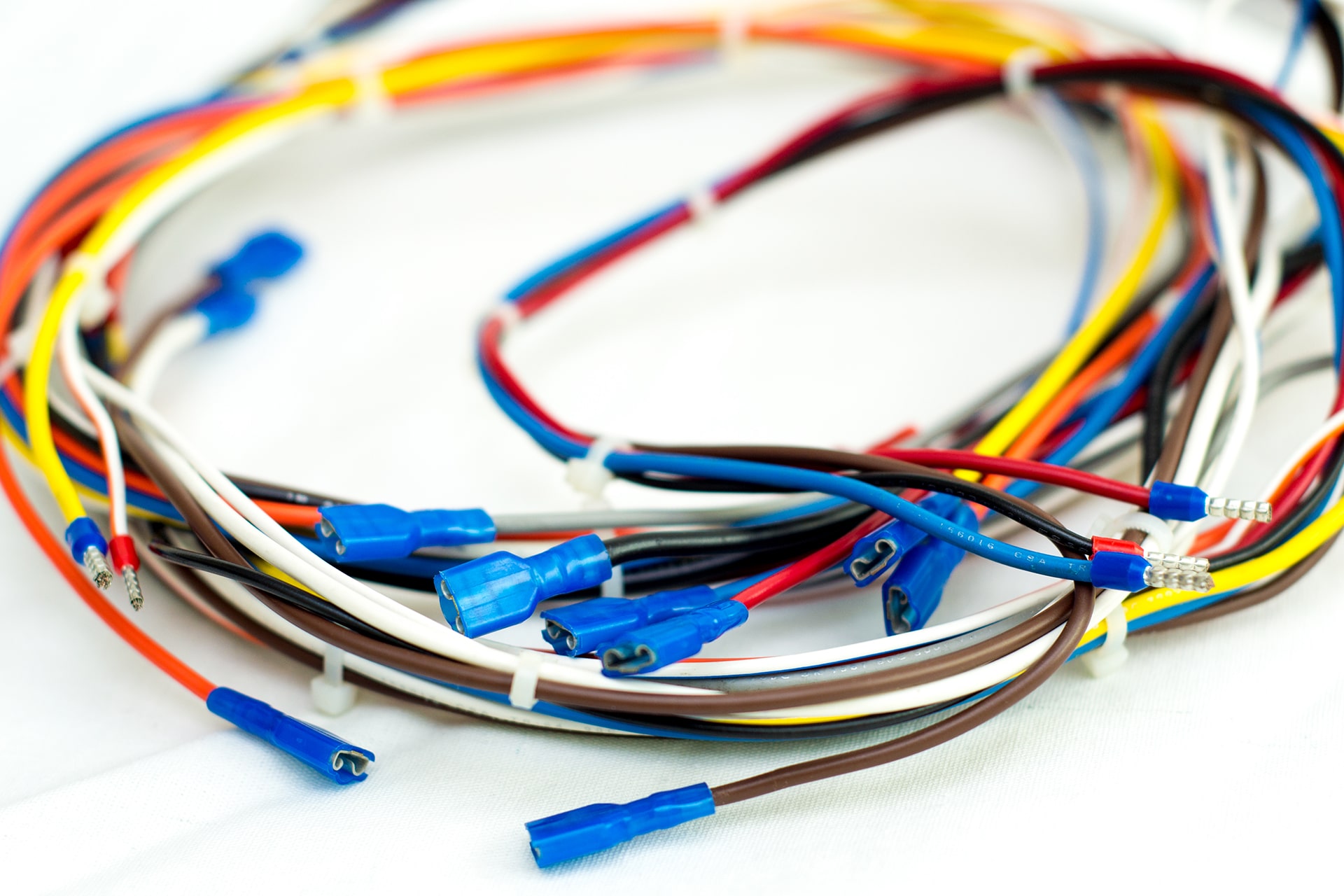

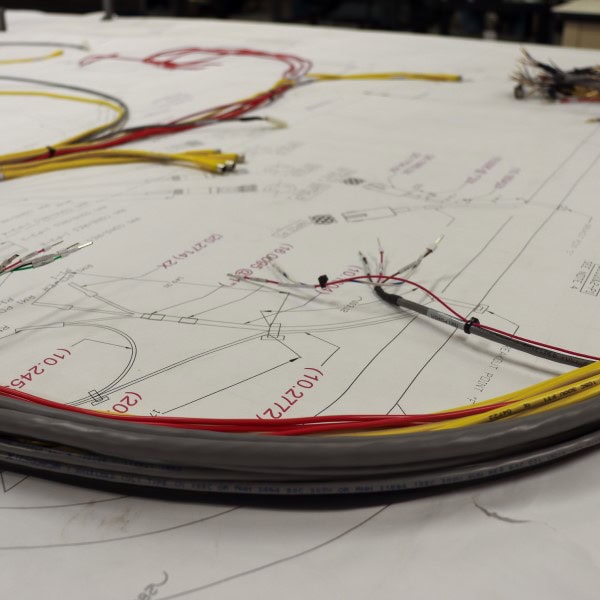

Custom Wire Harness

ECM manufactures a wide variety of wiring harnesses, from single conductor jumpers to peg board assemblies with hundreds of break outs. Specializing in custom applications from light-duty lead wire to heavy-duty cable assemblies and precision wire harnesses.

Cable Assembly

Cable assemblies provide cable strain relief and improved pull strength to protect cables and wires in harsh environments. ECM can over-mold connectors and strain reliefs to create high-quality and flexible assemblies. Customize with a company logo, product designator, or other custom labeling.

Power Cord Assembly

We offer a range of domestic, international, and hospital-grade power cords designed to meet or exceed all safety and operation standards. ECM provides a variety of standard and custom manufactured power cords with the ability to scale production from our multi-site approach in the US, Mexico, and Asia.

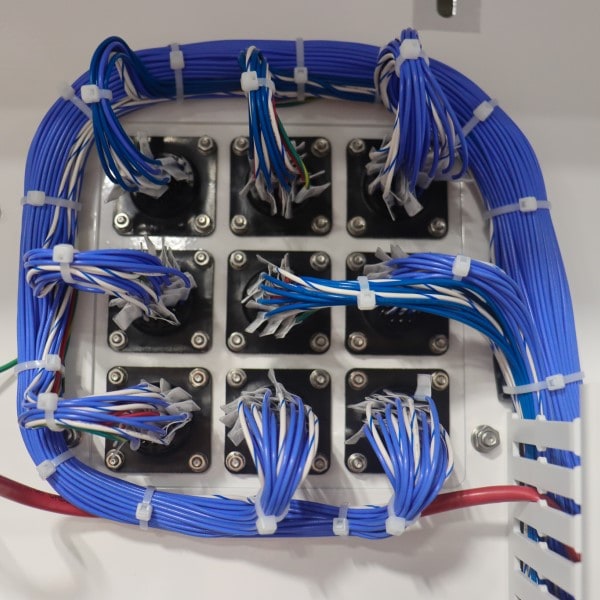

HIGH-LEVEL ASSEMBLY

Simplify production, manage floor space, reduce inventory, and more with ECM’s contract manufacturing of High-Level Assemblies (HLA’s). Through advanced technologies and in-house assembly solutions, we can support customers in automotive, medical & life sciences, alternative energy, military, and commercial & industrial industries.

PANEL ASSEMBLY

We can build UL508A-certified panel assemblies from your prints and specifications. We utilize an operations process involving in-house assembly solutions. We can simplify production, manage floor space, and keep costs lower while bringing your custom panel assembly designs to life by taking care of all aspects of the supply chain and manufacturing ourselves.

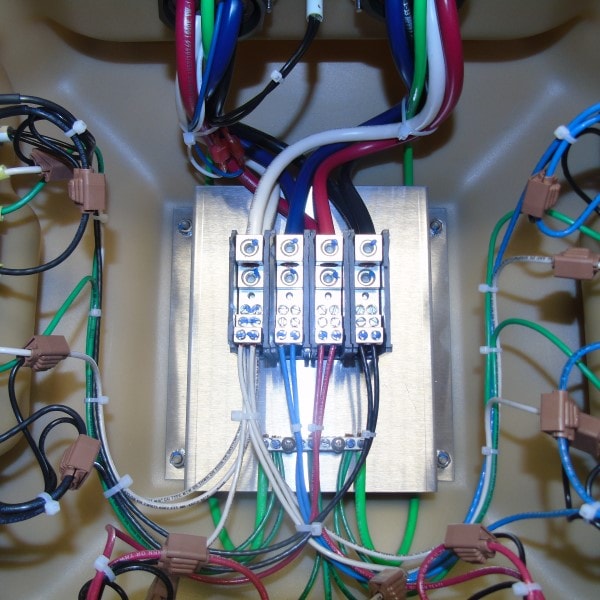

Custom Box Build

At ECM, we have the resources and skills to develop and manufacture a wide range of custom box-build electronic assemblies. Our box builds are high-level assemblies built to customer specifications, including engraving, electrical and function testing, ModCenter enclosure customizations, and the ability to meet UL508A approval.

Global Supply Chain

Simplify Your Business Model with Electronic Manufacturing Services (EMS) from ECM

Between supply shortages, long lead times, and cultural barriers, global outsourcing can be a complex, time-consuming, and expensive prospect.

Leverage ECM’s comprehensive industry knowledge and trusted network of offshore supply partners to scale your electronic manufacturing project—safely, efficiently, and cost-competitively. Through the power of our manufacturing facilities worldwide in China, Taiwan, Vietnam, Indonesia, and Thailand, we can offer comprehensive solutions for Electronics Manufacturing and Supply Chain Services.

From procurement to engineering to manufacturing, warehousing, packaging, and distribution, our programs are designed to help you deliver high-quality electronic assemblies more efficiently and cost-effectively than ever.

Electronic Manufacturing Services (EMS) for Small & Large Scale Production

Receive the benefits of working with a local US-based company alongside the production capabilities of a global manufacturer. We have team members on-site at our manufacturing facilities worldwide to support projects for high, medium, and low-volume production runs. Such programs, paired with our global distribution facility, allow ECM to create a Just-In-Time (JIT) environment for our customers to reduce or eliminate lead times and cut out unnecessary expenses from their supply chain. Reduce Total Cost of Ownership (TCO) by allowing ECM to manage your complex supply chain and ensure repeatable quality in low-cost manufacturing regions.

Discover How Efficient Your Supply Chain Can Be with ECM

Whatever level of support you require, we have the knowledge and resources to help your business streamline production, reduce overhead costs, and achieve your annual goals.

Supply Chain Services We Offer:

- Identification and Qualification of Manufacturing Partners

- Engineering Support

- Product Development

- Quality Assurance

- Document Control

- Logistics Management

- Testing & Certification

- Kitting & Packaging

- Warehousing & Distribution

Electronic Products We Source:

- Wire Harnesses

- Ultrasonic Welding

- Thermal Sensors & Controls

- Flat Cable, Ribbon Cable, IDC Connectors

- Cable Assemblies & Power Cords

- Over Molded Housings and Strain Reliefs

- Interface Cables, Sensor Cables, I/O Cables

- USB, USB-C, Micro USB, HDMI, and Lightning

- EV Charging Cables

- Domestic & International Power Cord Configurations

- Electro-Mechanical Assemblies and Electronic Manufacturing Services (EMS)

- PCBA and Box Build

- LED and Flexible LED Strips

- Smart Power Products

- Power Supplies, Power Adaptors, Power Strips, Chargers, & Battery Packs

Warehousing Solutions for Your Global Supply Chain

Warehousing Solutions for Your Global Supply Chain: Avoid filling up your shelves or paying a third-party logistics warehouse to store your products.

Trust a company that who knows your product and your distribution requirements to provide a solution that will save you time, money, and space.

ECM has the capability to stock products in the United States as required, keeping the pipeline full and helping you meet your internal or customer fulfillment strategies.

Our distribution center is conveniently located in Mendota Heights, Minnesota to stock your products that we manufacture in Mexico or Asia and deliver them to your North American locations.

Global Quality Compliance

- Certificate of Origin (COO)

- HTS Codes

- REACH & RoHS

- International Agency Approvals

Avoid Tariffs By Sourcing Electronic Assemblies from Vietnam

Recent revisions to the Harmonized Tariff Schedule (HTS) imposed a 25% tariff on power cords and cable assemblies manufactured in China to enter into the United States.

To lower costs and avoid supply chain disruptions, ECM has expanded its global footprint to include trusted supply partners throughout Vietnam.

With a growing electronic manufacturing sector and a skilled labor force, Vietnam presents an ideal solution for avoiding the tariffs & other challenges currently facing China.

ECM has a network of manufacturers throughout Vietnam with the equipment and capabilities necessary to meet the quality requirements of any industry without subjecting your project to high tariffs and labor costs.

We can maintain local inventories and ensure on-time delivery when and where you need it.

Faster Assembly:

By providing all of the necessary components in one kit, production can be done in one quick, streamlined process, instead of waiting for each individual part to be shipped and picked. Each kit is counted as one SKU, so your pick/pack costs are lowered.

- Packaging Capabilities

Kitting services that meet your product needs help companies be more efficient and cost-effective. Our kit packaging capabilities are:

- Bulk Packaging

- Self-secured Hank

- Fold and Tie Hank

- Coil and Tie

- Individual Bagging

- Custom Clamshells for Retail Packaging

- Labeling Services

We offer a large range of labeling options featuring part numbers, model numbers, bar codes, and other relevant information as needed.

- Part Number

- Revision Number

- Bar Code

- Customer Name

- Project Name

- Caution Labels

- Custom Printing on Bag

- Traceability

When it’s important to our customers, we can ensure product/part traceability both forward, all the way to end user in field or in reverse, throughout our supplier’s process. In addition, we can track all material through barcoding and lot tracing.

- Rapid Prototyping

Rapid prototyping for kitting services is offered along with value-added value engineering, when reviewing specifications and CAD documents. This helps our customers get to market faster.

Molding & Over-Molding

ECM’s molding and over-molding capabilities are engineered to deliver mechanical resilience, environmental protection, and electrical performance in high-reliability applications. By encapsulating critical components, we extend product lifecycles and maintain functionality in environments where conventional assemblies are prone to failure.

Our Capabilities Include:

- Over-molded Connectors – Precision-engineered for optimized strain relief, ingress protection, and mechanical stability under repetitive use and load conditions.

- Custom Molding Solutions – Designed to exact customer specifications, supporting complex geometries, material compatibility, and integration into medical, industrial, and enterprise technology platforms.

- Environmental Protection – Engineered resistance to vibration, fluid exposure, chemical agents, and temperature extremes to ensure continuous operation in demanding settings.

- User-Centric Design – Over-molded finishes that enhance ergonomics, improve handling, and provide a professional, production-ready appearance.

From enterprise hardware to medical devices and automotive systems, ECM applies advanced molding and over-molding processes that reinforce reliability, safeguard performance, and reduce field failures across critical applications.